Airbus producing COVID-19 PPE University of South Alabama Health

Eric Cleveland, part of the Airbus team that 3D-printed personal protective equipment for the University of South Alabama’s USA Health, holds up a completed face mask at the Airbus Final Assembly Line facility in Mobile. (Image courtesy of Airbus)

Airbus’ production and engineering teams in Mobile have teamed up with the University of South Alabama to produce 3D-printed, reusable face masks and mask tension release bands for medical personnel on the front lines of the COVID-19 pandemic.

Andrew Gumpert, an engineer at the Airbus Engineering Center in Mobile, wears a face mask with a 3D-printed tension release band while producing more of the bands for University of South Alabama Health workers. The tension release bands make protective face masks more comfortable for health workers who must wear them continually during their work on the front lines of the COVID-19 pandemic. (Image courtesy of Airbus)

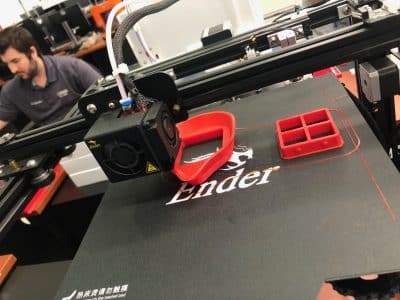

The Airbus team is making the masks and bands for medical personnel at USA Health, including University Hospital, Children’s & Women’s Hospital, the Mitchell Cancer Institute and the Physicians Group. The team hopes to produce 500 masks, which are reusable and washable, over the next three weeks, along with about 75 tension release bands per day. The masks will allow multiple uses of personal protective equipment (PPE), and the bands help the masks fit more comfortably.

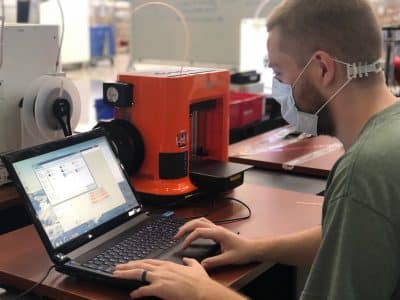

The masks and bands will be produced on 3D printers provided from Airbus’ production and engineering facilities, Flight Works Alabama and the University of South Alabama, using designs from the National Institutes of Health 3D Print Exchange COVID-19 Supply Chain Response file repository.

The Airbus team and Matthew Reichert, University of South Alabama associate professor of chemistry, have been printing prototypes, working to find the right products with Dr. Benjamin Estrada, professor and pediatric infectious diseases physician at USA Health, and his team.

Components of reusable face masks are completed on a 3D printer at Airbus’ Final Assembly Line facility in Mobile, prior to donation to the University of South Alabama for use at USA Health facilities. Pictured in the background is Eric Cleveland, part of the Airbus team that 3D-printed the personal protective equipment. (Image courtesy of Airbus)

Nick Simpson, a leader at Airbus’ Mobile production facility who specializes in process optimization and planning, is one of the many project participants.

“I’m excited to be helping the local medical community using the skills I and other team members normally use for making things fly,” Simpson said. “We’ve had some very clever people working on this, and we are gratified to help our local medical teams where and when it’s most needed.”

Andrew Gumpert, John Ding and Laurent Samson from the Airbus Engineering Center are coordinating 3D printing projects for Airbus, and thought this would be a great opportunity to contribute their knowledge and experience to benefit the community.

“We wanted to work on this project because we believe in the potential of this technology in making a difference in our fight against COVID-19,” Ding said. “It’s been great bringing this team together for a good cause.”

Airbus’ production of 3D-printed PPE, as well as donations of tens of thousands of face masks in the Mobile area in support of health care and first responder teams, has allowed Airbus to leverage its company and employee resources to assist communities fighting the COVID-19 pandemic.