Tour empowers future engineers, customers

The heat was on. But the students visiting Alabama Power’s Technology Applications Center (TAC) in Calera didn’t sweat it.

That’s because they were witnessing electricity’s versatility, power and potential in action.

The students, from Carver High School in Birmingham, were there Thursday Feb. 5 to experience the many ways electricity can improve their way of life. They were part of Academy Engineers, a career-oriented academy within the school funded in part by grants from the Alabama Power Foundation.

The budding engineers were right at home at the TAC, where Alabama Power looks to the future to help its customers today.

“When you think of marketing, you think of increasing sales of electricity and the use of electrical products,” said Senior Market Specialist Marcus Givan. “But we are also in the business of trying to help customers use those products efficiently and effectively.”

Hands-on learning part of TAC tour

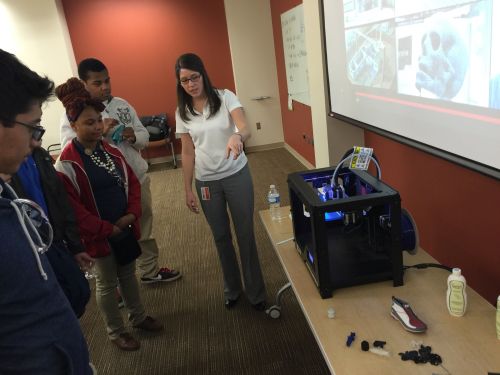

The tour of the TAC covered numerous cutting-edge applications and technologies. Students took turns handling a whirring 3D printer or pointing an ultrasonic gun to measure wasteful leaks.

At one point Givan turned up the heat with four massive 11 kW infrared wall heaters, used to warm up large warehouses or dry out industrial products. By contrast, a typical office space heater under your desk uses about 300 watts, or 1/36th the power.

“It was pretty interesting,” said Cameron Dansby, a sophomore interested in electrical and mechanical engineering.

“The biggest thing is the kids get hands-on experience,” said Project Manager Arthur Burrell. “Once you graduate from college, all that theory is just that. It’s about how you apply what you learned to the real world. Most engineering jobs are, ‘How do I solve a problem?’”

Indeed, the students saw how modern problems, such as the need for housing, could be solved with electricity. A film showed 3D printing technology in China molding and building 10 homes a day. The TAC’s smaller model was used to grind out plastic alphabet letters for the students to take home.

They were also ushered into a modern kitchen that uses induction heating to cook meals in a fraction of the time and with far less energy than typical gas-powered ranges.

“You can buy this commercial technology,” said Nicholas Hartmann, food services specialist. “In this high-velocity oven, you can cook a steak in 90 seconds and it will be well-done and juicy and tender. Not that you would want to cook a steak well-done, that’s sacrilege.”

Hartmann also recounted a recent cooking assignment using 1,800-watt induction technology. “At a planning meeting at Corporate Headquarters,” he said, “we cooked bananas Foster for 200 people. That’s the power equivalent to a hairdryer.”

Creating solutions to empower customers

Givan showed the students how Alabama Power helps both industrial and commercial customers get the most bang for their energy buck.

“Sometimes they request that we recreate an entire manufacturing process in the lab and test their product,” said Givan. “We’re trying to work with customers and make them as productive as possible.”

The students began the day with a safety briefing. After their tours, they enjoyed lunch and then had the opportunity to ask questions of the engineers.

“They made me feel like I was at home,” said sophomore Sabrina Lambert, who wants to be a civil engineer. “I didn’t know you could use electricity for all those different things.”

The TAC’s emphasis on energy efficiency and savings is reflected throughout the company.

For example, the “My Power Usage” app enables residential and industrial customers to monitor their daily energy use. Visit http://www.alabamapower.com/residential/save-money-energy/ for more information.